sources of error in brinell hardness test|how to find brinell hardness : importing indentation hardness measuring methods for metals (Brinell, Rockwell, Vickers) are discussed, for the ranges generally employed in engineering practice where universal metrological . webSport Betting | Come and play with us

{plog:ftitle_list}

Resultado da John Parker, July 5. The Man from Acapulco (Le Magnifique) 1973. This French Bond farce featuring Jean-Paul Belmondo and Jacqueline Bisset .

Typically the greatest source of error in Brinell testing is the measurement of the indentation. Due to disparities in operators making the measurements, the results will vary even under perfect conditions. Less than perfect conditions .

Step 1- Identifying the parameters for which uncertainty is to be estimated Step 2- Identifying all sources of uncertainty in the test Step 3- Classifying the uncertainty according to Type A or B .The Brinell Hardness Test is performed in a Brinell Hardness Test Unit. In this test method, a predetermined force (F) is applied to a tungsten carbide ball of fixed diameter (D), held for a .indentation hardness measuring methods for metals (Brinell, Rockwell, Vickers) are discussed, for the ranges generally employed in engineering practice where universal metrological .The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to 3000Kgf, for a specified time period, usually .

Brinell testing of a material with different ball diameters and test forces must be conducted within the same force-diameter index ("Brinell test procedure") in order to enable direct comparison .The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test .

non standard brinell hardness

Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading .The error in the performance of a Brinell hardness machine at each hardness level, under the particular verification conditions, is estimated by the percent error of the average of n . Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness .

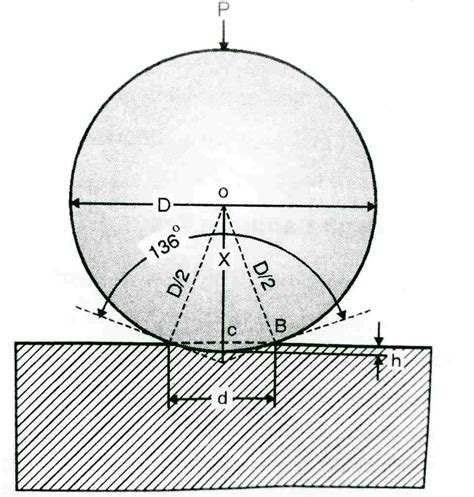

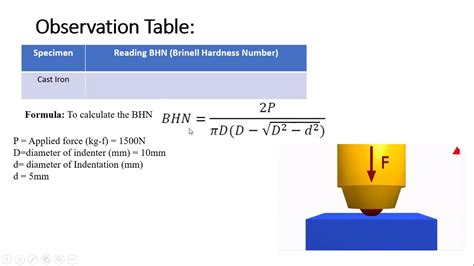

1. Test piece 2. Hardness testing machine 3. Environment 4. Operator 2.0.3 The table lists more than 20 sources of uncertainty which may all contribute significantly to the total uncertainty of a hardness measurement. These sources of uncertainty may not always contribute to every measurement at every level of the metrological chain illustratedIn the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. . and consequent risk of measuring errors due to wall formation. Therefore good illumination of the test indent is important for ensuring correct evaluation of the test indent (e.g. with the aid of a ring light).The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is . Hardness measurements by Vickers and Brinell indentations are liable to error, even when performed by experienced operators. The authors examine the problems involved in such measurements and the standards and specifications under which they are made. . ISO 156-1982.Metallic materials - Hardness test - Verification of Brinell hardness testing .

The Leeb Hardness Test, also known as the rebound hardness test, measures hardness by analyzing the rebound of an indenter, rather than the size of an indentation. It is portable and ideal for on-site testing of large and heavy components, offering a non-destructive method that causes minimal damage to finished parts and coatings.

Indentation hardness value is obtained by measuring the depth or the area of the indentation using different test methods. The Brinell hardness test method as used to determine Brinell hardness is defined in ASTM E10. It is typically used to test materials with a structure or surface too coarse to be tested by any other test method, for example .Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information about their hardness, toughness, and suitability for specific applications by subjecting materials to controlled indentation. Both hardness and strength are the important properties of laser forming repaired samples, but the laser forming repaired samples in this study were insufficient to perform extensive tensile .As part of the first lab, Brinell Hardness test will be used to determine the level of hardness applied from a 10 mm steel ball indenter onto a steel and aluminum disc under different applied force. EQUIPMENT & PROCEDURE

Your solution’s ready to go! Our expert help has broken down your problem into an easy-to-learn solution you can count on. See Answer See Answer See Answer done loading ISO 726-1982. Metallic materials - Hardness test - Calibration of standardized blocks to be used for Brinell hardness testing machines. Barbato and Desogus ISO 146-1984. Metallic materials - Hardness test - Verification of Vickers hardness testing machines HV O, 2 to HV 100. ISO 640-1984.

SCOPE. The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials. The relationship between material Brinell hardness and material stress–strain behaviors has been extensively studied. Both ISO/TR 10108 and GB/T 1172-1999 (Chinese national standard) have elaborated a conversion of hardness values and tensile strength values for steel [1], [2].In 2007, Janosec used the same strip steel as the measured material both in a . Hardness testing is thought to be one of the easiest tests to perform on the shop floor (Figure 1) or in the metallurgical laboratory (Figure 2) but it can be one of the hardest tests to do properly. . and microhardness tests (e.g. Vickers, Knoop). The Brinell test is used primarily for testing forgings and castings, particularly cast iron .The Brinell hardness testing method is used in various cases where large or rough surfaces, coarse-grained materials, or high loads are involved. It is particularly well-suited for testing the hardness of materials with relatively low hardness ranges, such as non-ferrous metals, castings, and softer steels.

Question: 1.Discuss the possible sources of errors (at least two) in Brinell hardness measurements. 2.why is it necessary to maintain P / D2 ratio of 30 for ferrous materials and 10 for non-ferrous materials is Brinell hardness test?

Analysis of the Brinell Hardness Measurement and the Main Sources of Errors. . Equally important in determining reliable hardness values is selecting a proper hardness tester for Brinell hardness testing. Many different universal hardness testers are available today, which combine hardness measurement at different scales through the use of . General Information about the Brinell Hardness Test. The Brinell hardness test involves pressing a hard ball indenter, usually made of tungsten carbide, into the material’s surface with a specified force. The diameter of the ball is typically 10 mm, but smaller diameters such as 2.5 mm can also be used for specific applications.

The Brinell hardness test is named after its inventor, Johan August Brinell. It involves applying a constant load or force to a spherical indenter made of hardened steel or carbide onto the surface of the material being tested. The indentation diameter is then measured optically. The Brinell hardness number (BHN) is calculated as the load .A method for predicting the ultimate tensile strength (S u ) of a material from Brinell-type hardness tests is described for several metals including steel, aluminum, and copper alloys. The prediction of S u is based on a consistent relationship between S u and a material’s hardness coefficient, K d . A simple experimental procedure for determining K d from indentation .

ISO 6506-1. Mets//ic maieria/s — Brine// hardness test — Part 1: Test method. ISO 6506-3:1999, Mets//ic materia/s — Brinell hardness test — Part 3: Calibration of reference blocks. 3 General conditions Before a Brinell hardness testing machine is verified, the machine shall be checked to ensure the following: a) the machine is properly .

Because the indentation ball is so much larger than in other testing methods, hardness values derived from the test provide a more representative average hardness of the part. More information about Brinell testing can be found in ASTM E10.

An alternative method is the Brinell hardness test, which uses a hardened steel (or tungsten carbide) ball indenter with a diameter D of, usually, 10 mm.This is applied under a load P of 500–3000 kg applied for 10–30 s.The diameter of the circular indentation d is measured in millimetres. The hardness number, (HB) is calculated using the following equation:Description of Brinell Test; ASTM A 370 says: “A specified load is applied to a flat surface of the specimen to be tested, through a hard ball of specified diameter. The average diameter of the indentation is used as a basis for calculation of the Brinell hardness number. The quotient of the applied load divided by the area of theApplication of Brinell Hardness Test in Various Industries. The Brinell Hardness Test finds extensive application across diverse industries, playing a crucial role in assessing material hardness and ensuring the quality and reliability of products. Below are some key industries where the Brinell Hardness Test is commonly employed. 1. ManufacturingThe most common hardness testing methods are Vickers, Rockwell and Brinell hardness testing, used for general testing of bulk materials and quality control during processing. 9.11.1. Vickers hardness testIn the UK and Europe, it is most common to use Vickers hardness testing (Figure 9.14). This is one of the oldest hardness testing methods, and .

how to find brinell hardness

Resultado da 15 de mai. de 2023 · Futemax.kim é uma plataforma de streaming de futebol muito popular no Brasil, mas há muitas outras plataformas disponíveis. .

sources of error in brinell hardness test|how to find brinell hardness